The global methanol industry is undergoing a fundamental transformation that extends far beyond traditional market dynamics of supply, demand, and pricing. What was once viewed primarily as a commodity petrochemical feedstock is rapidly evolving into a cornerstone of the global energy transition and circular economy.

Strategic investments in marine bunkering infrastructure, pioneering e-methanol production facilities, and innovative waste-to-methanol conversion technologies across Asia Pacific and Europe signal a market inflection point with profound implications for industrial decarbonization, maritime transportation, and sustainable aviation. This transformation represents not merely incremental change but a reimagining of methanol’s role in the 21st-century industrial ecosystem.

Asia Pacific

The Asia Pacific region’s methanol market expansion, projected at approximately 4.38% compound annual growth rate, reflects the convergence of multiple powerful demand drivers. China and India, the region’s industrial powerhouses, are simultaneously pursuing economic development and environmental responsibility objectives that methanol uniquely serves.

The chemical’s versatility across automotive fuel blending, formaldehyde production for construction materials, and feedstock for methanol-to-olefins plants positions it at the intersection of traditional industrial chemistry and emerging clean energy applications.

China’s approach to methanol deployment offers particular insight into how large emerging economies can leverage existing industrial infrastructure while advancing decarbonization goals. The expansion of methanol fuel blending programs and transportation applications demonstrates pragmatic policy design that achieves emission reductions without requiring wholesale replacement of existing vehicle fleets or fuel distribution systems.

This incremental approach to energy transition, while perhaps less dramatic than wholesale electrification, offers scalability and cost-effectiveness that may prove more politically and economically sustainable over time. The ramping operations of methanol-to-olefins facilities across Asia Pacific carry significant implications for global plastics and polymer markets. As these plants increase production, they provide an alternative pathway to light olefins that reduces dependence on traditional naphtha cracking.

This diversification of feedstock sources enhances supply chain resilience while potentially moderating price volatility in derivative markets. However, the environmental credentials of these facilities depend critically on the carbon intensity of methanol production itself, highlighting the importance of ongoing transitions toward lower-carbon methanol sources. The automotive sector’s growing methanol consumption, driven by increasingly stringent emission norms, illustrates how regulatory frameworks shape industrial chemical demand.

As Asia Pacific governments tighten air quality standards and carbon emission requirements, methanol’s role as a fuel additive and alternative fuel becomes more economically attractive relative to conventional gasoline and diesel. This regulatory pull, combined with technology push from improved engine designs and fuel systems, creates a reinforcing cycle that should sustain methanol demand growth even as electric vehicle penetration increases.

Europe’s Strategic Pivot

Europe’s methanol market evolution reflects the region’s broader commitment to industrial decarbonization and circular economy principles. The strategic initiatives underway spanning marine bunkering infrastructure, e-methanol production, and waste-to-methanol conversion represent a coordinated ecosystem approach rather than isolated projects.

This systemic perspective recognizes that successful energy transitions require not only production capacity but also distribution infrastructure, regulatory frameworks, and end-user adoption. Methanex Corporation’s expansion of marine fuel bunkering operations in the Amsterdam-Rotterdam-Antwerp region and South Korea represents critical infrastructure development that addresses a key barrier to methanol adoption in maritime transportation.

The shipping industry faces enormous pressure to decarbonize ahead of increasingly stringent International Maritime Organization regulations, but alternative fuel adoption has been hampered by concerns about fuel availability, supply chain reliability, and bunkering infrastructure. By establishing partnerships with TankMatch, Alpha Maritime, and Hyodong Shipping, Methanex is creating the physical and operational networks necessary for shipowners to confidently invest in methanol-fueled vessels.

The geographic positioning of these bunkering operations connecting Europe and Asia’s major shipping routes reflects strategic thinking about global maritime trade patterns. Ships operating on Asia-Europe trade lanes, among the world’s busiest, will have access to reliable methanol fueling at major ports on both ends of their routes. This infrastructure development should accelerate maritime methanol adoption by reducing the operational risks and uncertainties that have historically deterred shipowners from pioneering alternative fuels.

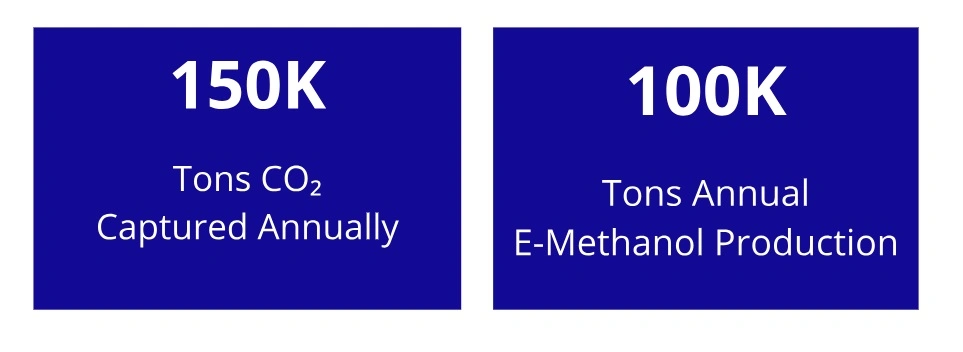

Sweden’s Flagship Three e-methanol project, developed by Liquid Wind and Umeå Energi, exemplifies the technical and environmental ambitions of Europe’s methanol renaissance. The facility’s planned annual production of 100,000 tons through renewable energy-powered electrolysis, combined with capture of 150,000 tons of biogenic carbon dioxide, demonstrates the viability of large-scale e-fuel production.

Locating the plant within the Umeå Eco Industrial Park enables industrial symbiosis, where waste heat, carbon dioxide, and other byproducts from existing facilities become valuable inputs for methanol production. The economic viability of e-methanol production depends critically on renewable electricity costs, carbon dioxide availability, and the price premium that customers will pay for low-carbon fuels.

Sweden’s abundant renewable energy resources provide a favourable foundation, but scaling e-methanol production globally will require similar conditions or technological advances that reduce production costs. Nevertheless, this project provides a crucial proof point that e-methanol can be produced at industrial scale, establishing technical benchmarks and operational practices that subsequent projects can refine and improve.

Norway’s waste-to-methanol initiative at the Mongstad refinery, led by NextChem in collaboration with Mana Group and Equinor, represents perhaps the most innovative circular economy approach within the methanol sector. Converting municipal and industrial waste into low-carbon methanol through NX Circular™ technology addresses multiple challenges simultaneously: waste management, fossil fuel displacement, and industrial decarbonization.

The project’s alignment with Fuel EU Maritime and Aviation regulations demonstrates how circular economy initiatives can meet specific regulatory requirements while creating new revenue streams from materials previously considered waste. The waste-to-methanol approach offers particular promise for regions with limited renewable energy resources but substantial waste streams requiring management.

While e-methanol production requires abundant clean electricity, waste-to-methanol can proceed wherever waste and appropriate conversion facilities exist. This geographic flexibility could prove crucial for establishing distributed methanol production networks that enhance supply security and reduce transportation costs.

Market Implications

The methanol market’s moderate price volatility in 2025 masks significant structural changes in price formation mechanisms. Traditional methanol pricing, largely driven by natural gas feedstock costs and conventional supply-demand balances, is increasingly influenced by policy incentives, carbon pricing mechanisms, and premium valuations for low-carbon methanol. This bifurcation between conventional and renewable methanol creates market complexity as different customer segments exhibit varying willingness to pay for environmental attributes.

In Asia Pacific, the balance-to-tight market conditions reflect robust industrial demand meeting supply constraints, particularly when natural gas curtailments disrupt production. These supply-side disruptions, often driven by policy decisions prioritizing residential heating or power generation over industrial feedstock supply, create price spikes that challenge downstream industries dependent on stable methanol costs.

The seasonal nature of these disruptions, combined with automotive and construction demand cycles, generates predictable but nonetheless disruptive price volatility that complicates procurement strategies and margin management. Europe’s methanol price outlook, supported by strong government incentives for renewable and waste-based production, suggests a trajectory toward stable-to-firm long-term pricing.

However, this stability may come at higher absolute price levels compared to conventional methanol. The critical question facing European chemical and energy companies is whether renewable methanol premiums will moderate as production scales or whether structural cost differences between fossil and renewable pathways will persist, potentially disadvantaging European industries in global competition.

Methanol’s Sustainable Shift

The methanol industry’s transformation from conventional petrochemical commodity to sustainability-enabling platform reflects broader shifts reshaping global industrial chemistry. Asia Pacific’s demand-driven growth and Europe’s supply-side innovation create complementary dynamics that should sustain market expansion while progressively reducing carbon intensity.

As marine bunkering networks expand, e-methanol production scales, and waste-to-methanol technologies mature, methanol’s role in industrial decarbonization will become increasingly central. However, realizing this potential requires continued policy support, technological advancement, and infrastructure investment across regions and value chains. The industry’s success in navigating these challenges will significantly influence the pace and trajectory of broader industrial energy transitions.