Imagine a world where the paint on your walls actively purifies the air you breathe, where aircraft wings heal their own micro-cracks mid-flight, and where building facades change colour to optimize energy consumption based on weather conditions. This isn’t science fiction it’s the emerging reality of smart coatings, a revolutionary technology that’s transforming every surface around us into an intelligent, responsive interface.

The standard paint can, a simple container of pigments and binders, is being transformed into something much more intelligent. Today’s smart coatings are designed at a molecular level, embedded with nanotechnology to make decisions, adapt, and respond to their environment autonomously. This is perhaps the most significant development in the field of surface engineering since the development of synthetic polymers.

The Science of Responsive Surfaces

In essence, smart coatings represent complex systems of materials that generate a continuum between the physical and digital universes. Conventional coatings simply occupy surfaces as passive barriers to the environment, while intelligent films are purpose-built with stimuli-responsive polymers, functional nanoparticles, and molecular switches capable of detecting and responding to the environment.

To illustrate, self-healing coatings are aesthetically fascinating; when a crack emerges, little microcapsules rupturing like tiny first-aid kits release healing agents that autonomously seal the crack. Chromogenic coatings utilize molecular structures like spiropyrans to take advantage of the arrangement of atomic configuration under exposure to light, resulting in dramatic colour changes that can regulate building temperatures or serve as visual indicators of environmental conditions.

These are not just improvements in existing technology; rather, they represent a shift away from reactive maintenance and move towards a model of reactive management of surfaces in an autonomous manner.

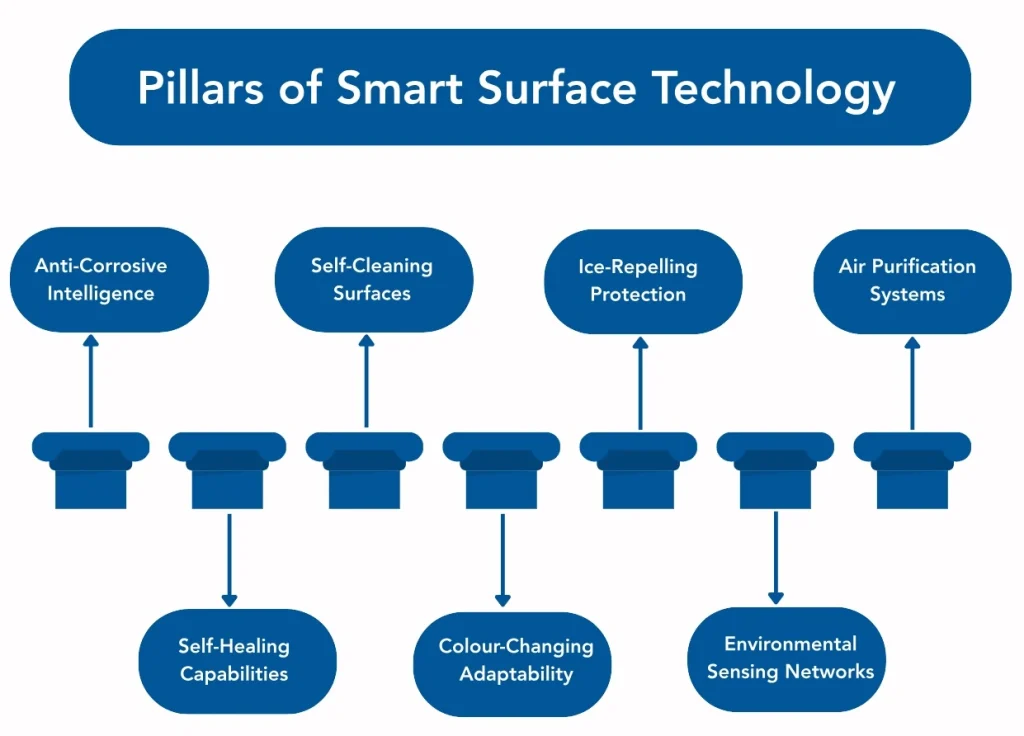

Seven Pillars of Smart Surface Technology

Anti-Corrosive protection: Innovative anti-corrosive protective coatings have changed the way we protect metal infrastructure. No longer relying on toxic chromate finishes, this technology deploys many eco-friendly inhibitors, encapsulated in nano capsules that only get deployed when corrosion occurs. It is akin to having a microscopic protective system with countermeasures that deploy on demand, when and where needed.

Self-Healing Capabilities: Perhaps the most biomimetic of all smart coatings, self-healing systems are inspired by how living organisms repair tissue damage. Using microencapsulation technology and dynamic polymer networks with reversible chemical bonds, these coatings demonstrate a notable self-healing mechanism capable of multiple healing cycles. This capability increases the life expectancy of critical components for aerospace and automotive systems substantially.

Self-Cleaning Adaptability: Self-cleaning coatings take advantage of the lotus effect and photocatalytic nanotechnology to achieve contact angles above 150°, resulting in water beading up and rolling off self-cleaning surfaces, synergistically carrying dirt and other undesired contaminant residue with it. Simultaneously, titanium dioxide nanoparticles oxidize organic pollutants under UV light, producing clean surfaces, even cleaning the air around the surface.

Colour-Changing Adaptability: Chromogenic coatings merge chemistry and visual design. The most dominant of these coatings are photochromic systems that respond to light intensity while thermochromic systems change their respective optical properties based upon temperature. These technologies are transforming architecture, enabling smart windows that automatically regulate solar heat gain and reduce energy consumption.

Ice-Repelling Coatings: Essential for aerospace and renewable energy applications, ice-repelling coatings consist of superhydrophobic topographies and low-surface-energy materials to avoid the creation of dangerous ice buildup. In this regard the focus is not only on efficiency but also on operational safety, reliability, and performance under extreme conditions.

Environmental Sensing Networks: Intelligent coatings can be applied as distributed sensor networks by introducing fluorescent dyes and biosensors to establish a detection mechanism for other hazardous environments, including structural corrosion and microbial contamination. This ability transforms passive surfaces into active sensing mechanisms, which could ultimately allow for early and accurate warnings of hazards to both infrastructure and health

Air Purification Systems: Most pertinent to our every-day lives, VOC-capturing coatings integrate various materials including porous polymers, zeolites, and metal-organic frameworks (MOFs) to selectively eliminate harmful volatile organic compounds (VOCs) from our daily indoor air. Every surface painted becomes part of an invisible network that is purifying our air during its use.

The Economic and Environmental Imperative

The worldwide smart coatings market is booming and is expected to surpass USD 1 billion by 2026. This growth is due to the convergence of three factors: stricter environmental regulations to eliminate harmful materials, demand for energy-efficient design options and construction materials, and the need for more durable infrastructure in a rapidly aging world.

All of this makes economic sense. While smart coatings may be more expensive upfront, the value they provide over the long term of increased service life, lower maintenance and better performance increases. A self-healing coating that can double the life of an aircraft piece or a chromogenic window film that can reduce energy consumption in a building by 30% pays for itself.

From an environmental perspective, smart coatings create a path for more sustainable materials. Smart coatings displace toxic chromates, reduce frequent repainting, and actively improve air quality all while achieving better performance consistently aligning with global sustainability targets.

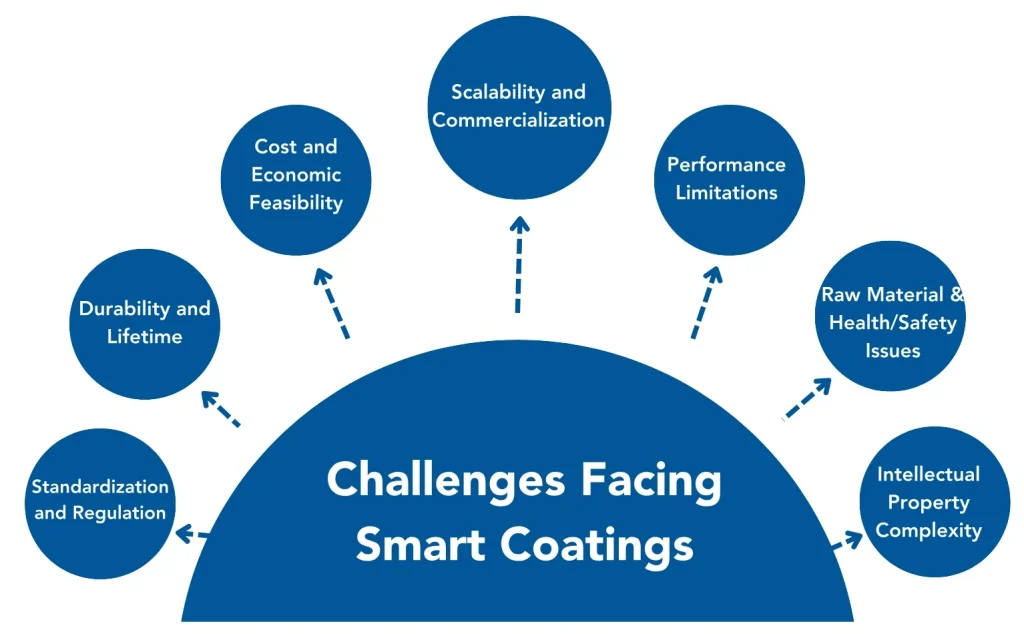

Overcoming the Innovation Valley

The transition from laboratory-scale smart coating prototypes to commercially viable products presents significant challenges across technical, economic, and regulatory domains. Scalability and manufacturing consistency represent primary barriers, as precise nanoscale engineering demands sophisticated production processes difficult to replicate industrially.

This complexity directly impacts economic feasibility, where advanced materials and specialized processing create substantial cost premiums over conventional systems. While superior performance may justify higher costs, market acceptance requires clear return-on-investment demonstrations, particularly in cost-sensitive applications where value propositions must overcome established procurement practices favouring, proven alternatives.

Long-term performance reliability compounds commercialization difficulties, as smart coatings must preserve complex molecular functionalities under prolonged environmental exposure. These sophisticated features often degrade faster than traditional coatings, raising lifecycle concerns.

Additionally, absent standardized testing protocols create validation uncertainty, while intellectual property complexities complicate technology transfer. Raw material sourcing at commercial scales, combined with comprehensive health and safety evaluations of novel nanomaterials, adds complexity layers requiring systematic resolution for widespread adoption.

The Convergence Moment

We find ourselves at a unique crossroads in materials science. Developments in nanotechnology are enabling engineering at the molecular scale economically. Advancements in artificial intelligence and data analytics are facilitating the design of dynamic systems that are increasingly sophisticated. A growing awareness of the global environment is generating market demand for sustainable and multifunctional materials.

The merging of these three elements suggest that smart coatings are more than a technological novelty, but the future of the coatings industry. Just as smartphones changed ordinary communication devices to computing platforms that perform multiple functions, smart coatings will change ordinary protective films into intelligent multifunctional interfaces.

Envisioning the Intelligent Infrastructure

Looking forward, the possibilities stretch well beyond individual uses. We can imagine cities in which the building facades actively clean the air, while thermally regulating themselves for maximum energy efficiency. Or vehicles that are capable of self-reporting, diagnoses and liaising with fleet management systems. Or healthcare settings using antimicrobial surfaces that can autonomously recognize and respond to categories of pathogen threats.

This vision of intelligent infrastructure where every surface does all of this and more arguably represents a new paradigm for how we interact with our built environment. Smart coatings are the enabling technology that will make this transformation possible.

The transformation from passive paint to smart surface systems represents more than just technology; it is a rethinking of what materials mean in the context of their environment. As we navigate an increasingly difficult landscape around sustainability, infrastructure deterioration, and public health, smart coatings provide powerful and elegant tools that are simple to apply.

The paint can of tomorrow won’t just contain pigments and polymers; it will hold the building blocks of responsive, intelligent surfaces that adapt, protect, and enhance our world in ways we’re only beginning to understand. In this transformation lies perhaps the most compelling aspect of smart coatings: they don’t just coat surfaces they make them come alive.