Price-Watch’s most active coverage of Ethyl Acrylate price assessment:

- Industrial Grade Purity( ≥ 99%) FOB Shanghai, China

- Industrial Grade Purity(≥ 99%) CIF Nhava Sheva Port (China), India

- Industrial Grade Purity(≥ 99%) CIF Santos (China), Brazil

- Industrial Grade Purity(≥ 99%) CIF Mersin (China), Turkey

- Industrial Grade Purity(≥ 99%) CIF Nhava Sheva (South Korea), India

- Industrial Grade Purity(≥ 99%) FOB Busan, South Korea

- Industrial Grade Purity (≥ 99%) Ex-Mumbai, India

Ethyl Acrylate (EA) Price Trend Q3 2025

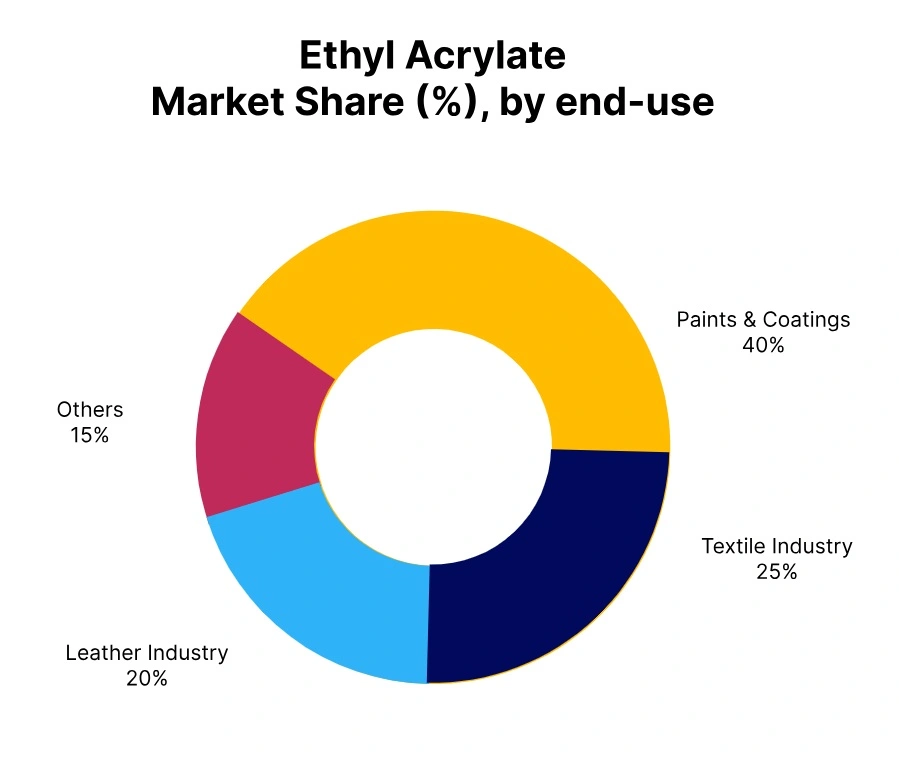

In Q3 2025, the global Ethyl Acrylate (EA) market displayed an average softening trend across key regions, driven by subdued downstream consumption and mild feedstock adjustments. Demand from coatings, adhesives, and polymer applications stayed consistent but cautious, with industrial buyers maintaining lean inventories amid cost pressures. Export activity from Asia to Latin America, the Middle East, and India remained steady but limited by competitive offers and currency fluctuations.

Production rates were stable, ensuring sufficient supply without sharp volatility. Ethyl acrylate price trend mirrored controlled declines, with regional variations influenced by local demand, trade flows, and logistical efficiency. Market fundamentals suggest a cautious yet balanced outlook heading into Q4 2025.

China: Ethyl Acrylate Export Prices, FOB Shanghai, China, Industrial Grade (>99%).

In Q3 2025, Ethyl Acrylate prices in China followed a downward trajectory, influenced by weaker export inquiries and softer domestic demand in coatings and adhesives. Exporters maintained steady shipments to Southeast Asia, India, and Latin America, while buyers adopted cautious procurement strategies amid adequate inventory levels. The Ethyl Acrylate price trend in China reflected stable feedstock availability, though softening propylene and acrylic acid costs encouraged modest price reductions.

According to Price-Watch, in September 2025, Ethyl Acrylate price trend in China under FOB Shanghai decreased by 1.07%, signalling a soft market tone. Overall, fundamentals remained balanced, and prices are likely to remain stable into Q4 2025, barring a strong pickup in downstream demand.

Turkey: Ethyl Acrylate Import Prices, CIF Mersin (China), Industrial Grade (>99%).

In Q3 2025, Ethyl Acrylate prices in Turkey softened moderately due to decreased import demand from coatings, adhesives, and industrial polymer sectors. Chinese suppliers maintained regular shipments, but buyers slowed spot purchases, supported by stable domestic inventories. Logistic efficiency and manageable freight rates ensured consistent supply, while competitive import offers contributed to mild downward pressure.

The Ethyl Acrylate price trend in Turkey showed a balanced market environment, with steady production supporting adequate availability. In September 2025, Ethyl Acrylate prices under CIF Mersin went down by 1.33%, reflecting softness in the market. Ethyl Acrylate Prices are expected to stay stable in Q4 2025, supported by measured procurement and consistent industrial activity.

Brazil: Ethyl Acrylate Import Prices, CIF Santos (China), Industrial Grade (>99%).

In Q3 2025, Ethyl Acrylate prices in Brazil experienced a slight decline, shaped by limited import demand and cautious downstream consumption in coatings, adhesives, and polymer segments. Competitive offers from Chinese suppliers, combined with sufficient local stock, prompted buyers to use conservative procurement strategies. The Ethyl Acrylate price trend in Brazil reflected steady consumption in industrial polymer and adhesive sectors, preventing sharp price movements despite the decline.

In September 2025, Ethyl Acrylate prices under CIF Santos decreased by 1.09%, indicating a soft market tone. Overall, fundamentals stayed balanced, with controlled pricing likely to continue into Q4 2025, supported by stable supply and manageable inventories.

South Korea: Ethyl Acrylate Export Prices, FOB Busan, South Korea, Industrial Grade (>99%).

In Q3 2025, Ethyl Acrylate prices in South Korea showed cautious softness, influenced by subdued domestic and export demand. Downstream industries, including coatings, adhesives, and polymer manufacturers, maintained cautious procurement amid stable inventory levels. Export activity remained consistent but limited, while production rates stayed stable without disruptions.

The Ethyl Acrylate price trend in South Korea indicated a balanced-to-soft market tone, with selective downward adjustment reflecting measured buying. In September 2025, Ethyl Acrylate prices under FOB Busan fell by 0.55%, highlighting mild softness. Overall, fundamentals were stable, and Ethyl Acrylate prices are expected to maintain a slight downward bias into Q4 2025 unless downstream demand strengthens materially.

India: Ethyl Acrylate Import Prices; CIF Nhava Sheva (South Korea), Industrial Grade (>99%).

According to Price-Watch, In Q3 2025, Ethyl Acrylate prices in India had a slight softening, influenced by moderate downstream demand from adhesives, coatings, and polymer sectors. Buyers maintained lean inventories, and currency fluctuations affected landed costs, contributing to cautious procurement. Import volumes from South Korea remained stable, with reliable feedstock supply ensuring consistent deliveries.

The Ethyl Acrylate price trend in India reflected balanced supply-demand conditions, preventing sharp movements. In September 2025, Ethyl Acrylate prices under CIF Nhava Sheva declined by 0.33%, signalling a steady-to-soft market tone. Overall, market fundamentals suggest stability, with minor correction possible depending on seasonal downstream demand recovery, and Q4 2025 prices are expected to remain largely rangebound.