Artificial intelligence and automation technologies are revolutionising the petrochemical manufacturing industry across the globe. These industries heavily rely on AI, big data, IoT, digital twins, and smart automation to optimize operations, reduce costs, improve safety along with boost sustainability. The integration of AI in Oil & Gas market enables real time monitoring, predictive maintenance, supply chain optimization, and advanced process control which in result helps in reducing downtime and environmental impact.

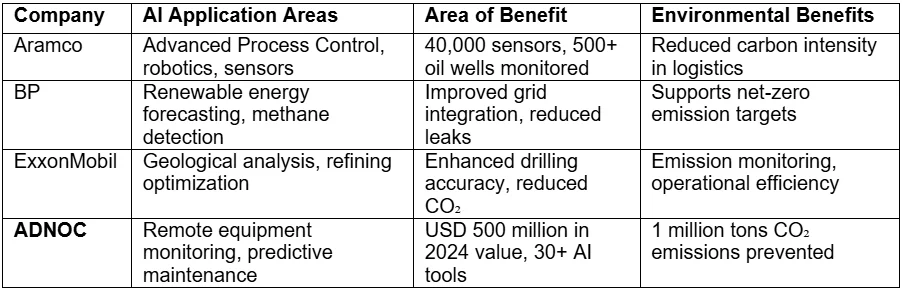

This article breaks down how global leaders like Aramco, BP, ExxonMobil, and ADNOC are leveraging AI driven solutions to pioneer smarter, more efficient processes.

We will review India’s rapidly evolving petrochemical sector, which is embracing AI driven digital transformations in line with national objectives such as Digital India, Atmanirbhar Bharat and the goal of achieving Net Zero by 2070. Significant industry collaborations along with an increase in refining capacities continue to position India to become a global hub for smart manufacturing.

In the final section, we provide a market outlook that details growth projections and the ongoing impact of AI on the future of the petrochemical industry, both globally and in India.

AI Driving Efficiency & Sustainability in Petrochemicals

Leading global petrochemical companies are incorporating artificial intelligence and automation into their operations to achieve higher productivity and better environmental performance. For example, Saudi Aramco has deployed 40,000 sensors to monitor over 500 oil wells, establishing the first advanced process control system in a conventional oil field. Their Khurais and Abqaiq plants utilize smart sensors, robotics, and AI-driven analytics to automate inspections and predictive maintenance, reducing manual labour and operational risks.

BP leverages AI to optimize renewable energy production by accurately forecasting solar and wind output. They also utilize AI to detect methane leaks and improve refining processes, which supports their goals of achieving net zero emissions. Similarly, ExxonMobil employs AI models to enhance drilling accuracy, increase refining efficiency, and monitor emissions, reducing environmental impacts through real time operational insights.

Abu Dhabi National Oil Company (ADNOC), another key player, generated USD 500 million in value from AI adoption in 2024. With 30+ AI tools deployed, they remotely monitor equipment, enhance resource mapping, and automate operations with solutions like SMARTi and Robowell. This helped prevent an estimated 1 million tons of CO₂ emissions between 2022 and 2023, underscoring AI’s environmental contribution.

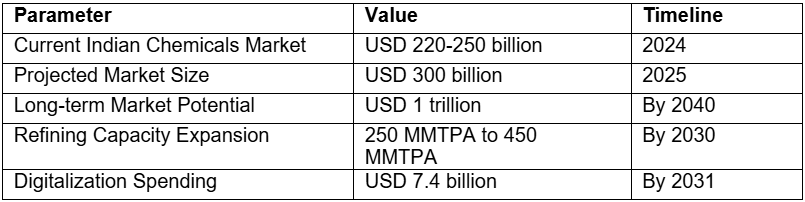

The global chemicals digitalization market has been valued at USD 14.83 billion in 2023, with a projected compound annual growth rate (CAGR) of 23.1% through 2030. This rapid expansion is driven by growing adoption of AI, IoT, and automation technologies aimed at improving operational resilience and sustainability.

India’s Petrochemical Upgrade: AI at the Core

India’s petrochemical and refining industries have begun aggressively adopting AI and digitalization technologies to meet growing demand and sustainability goals. A landmark collaboration between AVEVA, a global industrial software leader, and HPCL Mittal Energy Limited (HMEL) exemplifies this transformation. The partnership is set to leverage AI driven digital twins, real time operational intelligence, predictive maintenance, and process optimization to modernize the Guru Gobind Singh Refinery in Bathinda, Punjab, which includes:

- Crude oil refinery capacity of 11.3 million metric tons per annum (MMTPA)

- Multi-feed cracker with 1.2 MMTPA capacity

- Polyethylene and polypropylene plants of 1.2 MMTPA and 1.0 MMTPA, respectively

This initiative aligns with India’s Digital India and Atmanirbhar Bharat programs and supports the ambitious Net Zero 2070 target while preparing the sector for a significant increase in refining capacity from 250 MMTPA (Million Metric Tons Per Annum) today to 450 MMTPA by 2030.

Indian Market Growth & Digital Transformation Statistics

India is rapidly adopting Industry 4.0 technologies, including AI, IoT, and digital twins, in response to the projected tripling of demand for chemicals and increasing sustainability pressure. Digital transformation in the sector is essential for enhancing operational efficiency, reducing emissions, and ensuring energy security.

Smarter, Safer, Sustainable: The AI Advantage

AI and automation are fast becoming foundational pillars for the future of petrochemical and oil & gas industries worldwide. Global players are accelerating smart manufacturing investments through AI and automation, a trend reinforced by strong market projections.

Indian petrochemical industry reflects the same momentum. The domestic petrochemical market is set to almost double in the next decade, fuelled by AI-driven strategies that enhance efficiency, strengthen risk management, and embed sustainability at the heart of operations. Real-time analytics and predictive technologies will cut downtime, minimize disruptions, and reduce emissions, building smarter supply chains and resilient production systems.

What makes this transformation unstoppable?

A powerful mix of rising digitalization budgets, proactive government support, and strong public private collaborations. Together, these forces are setting new performance benchmarks.

Companies that lead this shift will unlock:

- Smarter resource allocation & agile production planning

- Lower costs and minimal downtime through predictive maintenance

- Safer operations via automated inspections & hazard detection

- Greener processes through advanced emissions monitoring and reduction

AI’s Future in Petrochemicals

Artificial intelligence and automation are no longer optional in the petrochemical industry. They are redefining its core. From global MNCs like Aramco and BP to Indian leaders such as HMEL and AVEVA, AI is now embedded across exploration, refining, supply chains, and sustainability. The impact is clear: smarter operations, safer plants, and a lighter environmental footprint.

With digitalization in petrochemicals projected to reach USD 14 billion globally and India’s petrochemical market heading toward USD 300 billion by 2025, staying adaptable is key to remaining competitive. Embracing AI-driven innovation isn’t just about efficiency; it’s about future-proofing the industry and leading the charge toward a sustainable and competitive tomorrow.

Frequently Asked Questions (FAQs)

How does AI improve safety in petrochemical operations?

AI automates hazardous tasks, monitors equipment health in real time, and detects safety hazards proactively, reducing human exposure and preventing accidents.

What is predictive maintenance, and why is it important?

Predictive maintenance uses AI to forecast equipment failures before they occur, minimizing downtime and costly repairs, which enhances operational efficiency.

How is AI helping India’s petrochemical sector grow?

AI enables real time process optimization, predictive maintenance, and supply chain improvements, supporting India’s goal to expand refining capacity and sustainability.

What are digital twins, and how are they used in petrochemicals?

Digital twins are virtual models of physical assets or processes that allow monitoring, simulation, and optimization in real time, leading to better decision making.

Stay updated with PriceWatch to explore how AI is redefining industry practices. Subscribe for updates or share your perspectives in the comments below. Stay connected for more insights on smart manufacturing transformations.

References:

https://corporate.exxonmobil.com/who-we-are/technology-and-collaborations/digital-technologies

https://www.aveva.com/en/about/news/press-releases/2025/aveva-and-hmel-sign-mou-to-drive-ai-powered-digitalisation-in-india-s-refining-sector/

https://www.reuters.com/technology/adnoc-says-ai-added-500-mln-extra-value-2023-2024-03-05/

https://www.pib.gov.in/PressReleasePage.aspx?PRID=2066135

https://www.adnoc.ae/en/news-and-media/press-releases/2023/%24500-million-in-value-generated-by-adnoc-through-deployment-of-ai-solutions-in-2023

https://www.ibef.org/industry/chemical-industry-india