Imagine the buildings of the future, buildings which are made up of recyclable or carbon-neutral materials, constructed and powered by renewable energy. How will that future look like?

Simple Answer- A sustainable future, a future that can be the cornerstone of intergenerational responsibility. A truly sustainable built environment would ensure that what we built can be inherited by future generation without any burden.

Yet, the two critical questions remain unanswered, how close are we in realising that future and is that future worth the effort?

The answer to second question is an unequivocal Yes, with resounding affirmation.

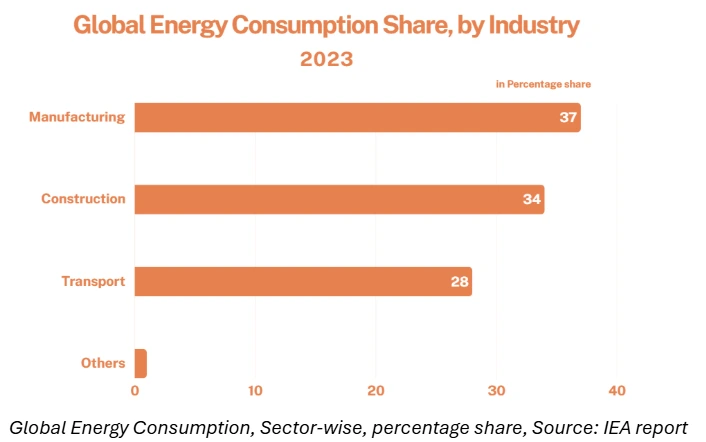

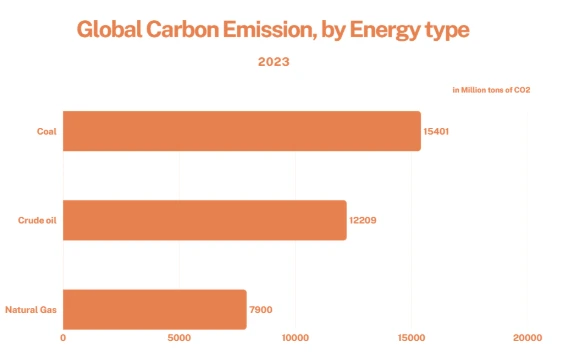

Construction industry is fundamental and gives structure to any economy. It is also solely responsible for significant energy consumption and global carbon-emissions. According to UNEP’s Global Status Report for Buildings and Construction, Construction industry is among the leading consumer of energy with 34%, behind Manufacturing with share of 37%, in terms of total global energy consumption. Furthermore, it is also responsible for one-third of total global carbon emissions.

Decarbonizing Construction through Renewable Integration

Addressing these two figures demands systemic changes, yet such transformations can pave the way toward the long-sought goal of sustainability. By making the entire construction process from material selection to structural development more carbon-neutral and sustainable, the industry can significantly reduce its carbon footprint.

Simultaneously, constructing and operating buildings powered by renewable energy diminishes dependence on fossil fuels, diversifies our energy portfolio, and indirectly curbs carbon emissions. In this way, the built environment can lead the transition to a carbon-neutral future an ambition first outlined in the Paris Agreement of 2015 through sustainable construction and operation.

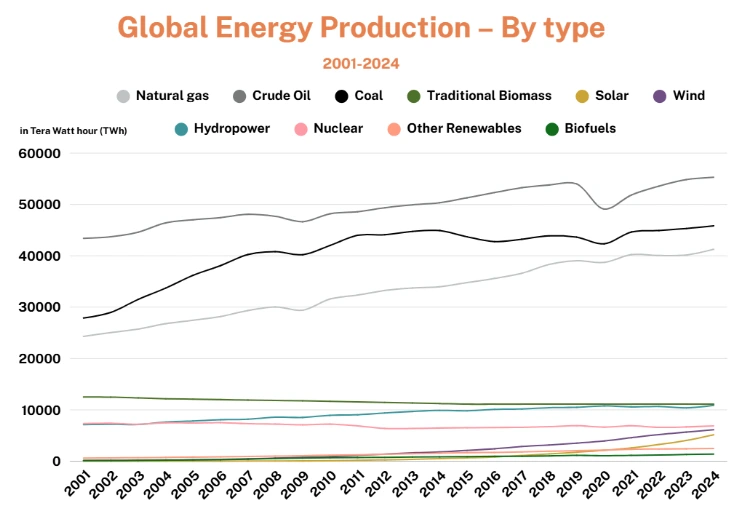

The construction and operation of built environment on renewable energy can simply be achieved by increasing the global renewable energy capacities via hydro, solar, geothermal, wind and other means. In the latest report published by International Energy Agency on Global Energy Review (2025), it has been found that renewables are the fastest growing in total energy supply with share of 38%, followed by Natural gas (28%), Coal (15%), Crude oil (11%).

Hence, buildings can be constructed, operated and powered by renewables, question is not of if but when.

In recent years, emergence of modular battery system which deploy on site and recharge through solar energy has become a popular and sustainable solution. These battery system power electrical machines, power tools and other equipment on construction sites, thereby offsetting tons of CO2 production and reducing the dependence on diesel-powered machinery and equipment.

For sustainable construction, the use of renewable and recyclable materials in building projects is mandatory which not only minimize energy consumption but also reduces waste production. These materials can be, responsibly sourced Wood (sustaining ecological balance and human requirements), Sustainable Concrete (Use of Supplementary Cementitious Materials like Fly Ash, Slag and others), and wool-reinforced bricks. Although nations have adopted various routes but the goal of achieving sustainability in their construction sector remains central to the discourse.

Regional Paths Reshaping Global Construction

Europe has been emphasizing sustainable construction and encouraging sustainable construction practices. According to the latest report by UNEP Global Status report, the use of recycled steel and cement reached 18% by early 2024, highlighting the commitment to the same.

In search of sustainability, Japan has undertaken one of the most ambitious projects in construction history with its W350 Project by Sumitomo Forestry. The project plans to build a 70-story hybrid skyscraper in Tokyo made up of timber (90%) and steel (10%). While the construction hasn’t started, the plan has taken concrete shape and expected to be finished by 2041.

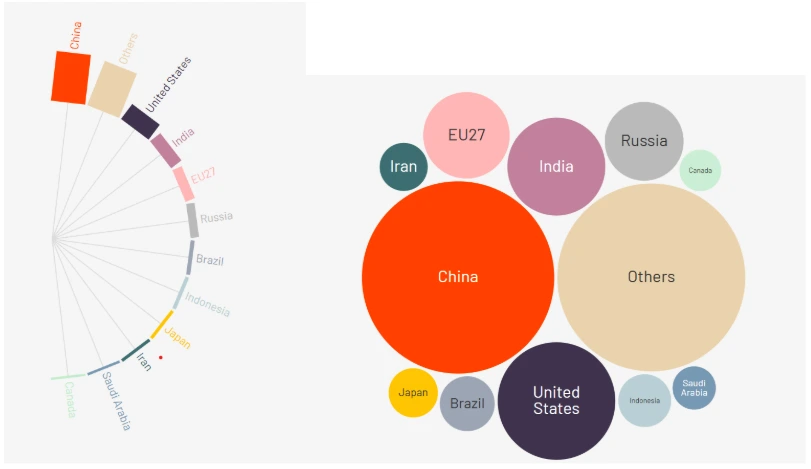

In contrast, China and India have taken a more subtle path to ensure sustainability in their respective construction sectors. Both are heavily employing and mandating the use of Fly Ash in the construction of building via Fly Ash bricks or mixing it with cement making it more sustainable. Portland Pozzolana Cement or PPC Cement is that Fly-Ash blended ready-mix concrete which has been used in major projects including roads, bridges, and building foundations. The use of fly ash in construction has not only brought sustainability into the picture but also curtailed the pollution in both the countries. (Fly Ash is a pollutant produced during coal combustion in thermal power plants as it contains harmful heavy metals like Arsenic, Mercury and Cadmium.)

Plastics, Innovation, and the Path to Sustainable Building

Another critical element in this sustainability journey can be the application of used plastics. By repurposing and recycling plastics into durable long-lasting building materials, construction industry can reduce its waste burden and offset its demand for virgin materials. Companies like Ethiopia based Kubik and Argentine Arqlite are actively transforming plastics into building materials while becoming multi-million-dollar green businesses.

In USA, experimental Post Rock, a recycled plastic-based prototype sourced from automotive industry has gained traction. This material has the qualities of natural stone and been designed to reduce carbon emission by reusing plastics from automotive industry.

Despite such advances, the journey to full sustainability remains long. The progress can be seen, however, a lot more effort should be involved on the part of all stakeholders. Clients must consider using the materials that are sustainable in their projects; builders are to make sure that materials of recycled origin should be easily accessible; and recyclers are obliged to ensure a stable and quality supply chain. At the same time, on-going innovation needs to continue to supplement and speed up this transformation.

Sustainable Construction Starts with Collaboration

In conclusion, to answer the first question, the future envisioned in the beginning of this article is still distanced however it is in sight. The construction enterprise has been taking serious steps in ensuring the sustainability of global construction industry. The West has been emphasizing reusing, repurposing and recycling of materials, including steel, cement and plastics, to be integrated into new building construction. Contrastingly, Asia has made innovation by developing alternative materials to be used in building assets, incorporating sustainability in its construction industry through different route.

However, sustainability will remain an ideal rather than a lived reality unless there are genuine, collective collaboration and coordination among all stakeholders. The question is no longer whether sustainable construction is possible, but whether stakeholders are prepared to abandon complacency and act decisively, ensuring that tomorrow’s buildings become testaments to responsibility rather than monuments to delay.

The momentum gained in 2024 and projected into 2025 highlights sustainability as an operational and regulatory imperative, driven by technological advancements, circular economy principles, and heightened global commitment. Yet, only through unified action across clients, builders, policymakers, and recyclers can the industry close existing gaps and realize a truly resilient, carbon-neutral built environment for future generations.

Sources and Further readings:

https://globalabc.org/sites/default/files/2025-03/Global-Status-Report-2024_2025.pdf

https://www.weforum.org/stories/2025/05/building-construction-emissions-data/

https://iea.blob.core.windows.net/assets/5b169aa1-bc88-4c96-b828-aaa50406ba80/GlobalEnergyReview2025.pdf

https://ourworldindata.org/energy-production-consumption

https://cen.acs.org/environment/Improving-concrete-one-worlds-worst/102/i14

https://www.4ocean.com/blogs/industry-news/upcycling-plastics-how-the-construction-industry-is-building-with-used-plastic

https://ourworldindata.org/emissions-by-fuel

https://edgar.jrc.ec.europa.eu/report_2024

https://www.iea.org/world/emissions