Price-Watch’s most active coverage of Electrical Steel price assessment:

- Non-grain (50PN800) 0.5mm EX-Busan, South Korea

- Non-grain (50WW800) 0.5mm CIF Laem Chabang (China), Thailand

- Non-grain (M15-C5) 0.5mm Del Alabama, USA

- Non-grain (50WW800) 0.5mm Ex-Mumbai, India

- Non-grain (50WW800) 0.5mm CIF Nhava Sheva (China), India

- Non-grain (50WW800) 0.5mm FOB Shanghai, China

- Non-grain (50WW800) 0.5mm FD-Sheffield, United Kingdom

- Non-grain (360) 0.35mm Ex-Mumbai, India

- Non-grain (1000) 0.5mm Ex-Mumbai, India

- Non-grain (B50A350) 0.5mm FOB Shanghai, China

- Non-grain (B50A600) 0.5mm FOB Shanghai, China

- Non-grain (B35A300) 0.35mm FOB Shanghai, China

- Non-grain (B35A440) 0.35mm FOB Shanghai, China

- 50JN470*A1-0.5mm FOB Osaka, Japan

- 35JN440*A1-0.35mm FOB Osaka, Japan

- 20JNEH1500*A1-0.2mm FOB Osaka, Japan

- Non grain (50C800) 0.5mm FOB Osaka, Japan

- Non grain (50C600) 0.5mm FOB Osaka, Japan

- Non grain (50C310) 0.5mm FOB Osaka, Japan

- 50JN470*A1-0.5mm CIF Haiphong (Japan), Vietnam

- 35JN440*A1-0.35mm CIF Haiphong (Japan), Vietnam

- 20JNEH1500*A1-0.2mm CIF Haiphong (Japan), Vietnam

- Non-grain (B50A600) 0.5mm CIF Jebel Ali (China), United Arab Emirates

- Non-grain (B35A300) 0.35mm CIF Jebel Ali (China), United Arab Emirates

- Non-grain (B35A300) 0.35mm CIF Jeddah (China), Saudi Arabia

- Non-grain (B50A600) 0.5mm CIF Jeddah (China), Saudi Arabia

- Non-grain (B50A600) 0.5mm CIF Manzanillo (China), Mexico

- Non-grain (B35A300) 0.35mm CIF Manzanillo (China), Mexico

Electrical Steel Price Trend Q3 2025

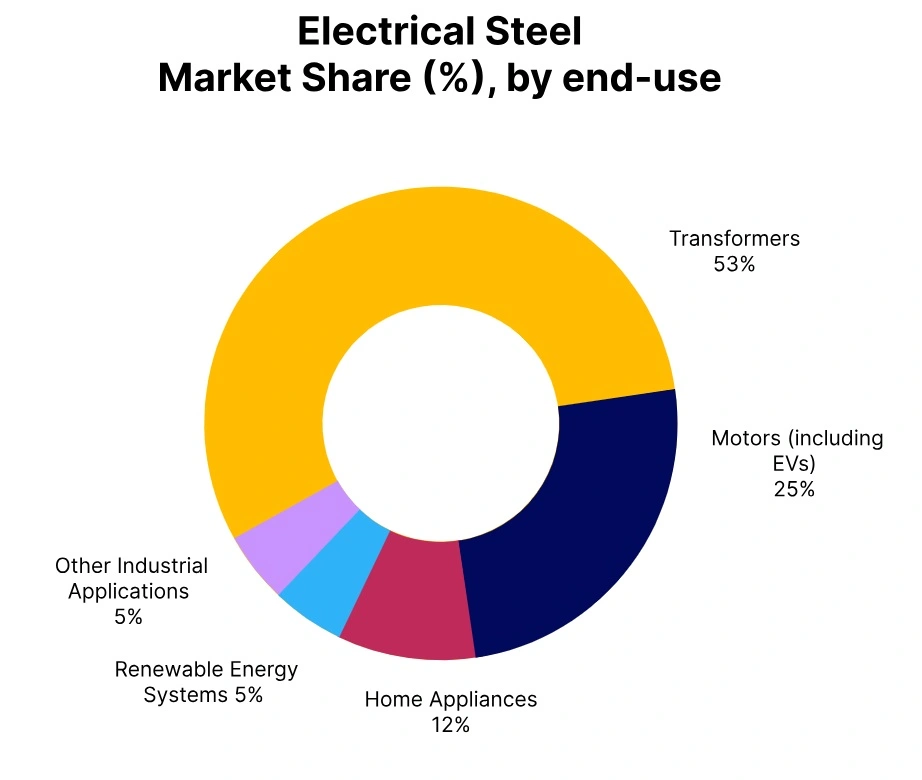

In Q3 2025, the global Electrical Steel market displayed a mixed trend, though the overall prices declined by around 1.07% during the quarter. While a few regions experienced brief periods of stability driven by industrial restocking, most major producers including China, India, the USA, and the United Kingdom reported a downward trajectory. The market softness was primarily linked to muted demand from transformer and motor manufacturing sectors, along with reduced activity in construction-related electrical equipment.

In contrast, Thailand and South Korea showed relatively stable price movements supported by domestic consumption. However, subdued export orders and high inventory levels in key markets kept overall sentiment weak, resulting in a marginal global price decline through the quarter.

USA: Electrical Steel Domestically traded prices Del Alabama, USA, Grade- Non-grain (M15-C5) 0.5mm.

According to PriceWatch, in Q3 2025, the electrical steel price trend in the USA inclined by 0.87% compared to the previous quarter, supported by steady demand from the electrical equipment, transformer, and EV motor manufacturing sectors. Increased investments in grid modernization and renewable energy projects contributed to a mild uptick in consumption.

Additionally, stable raw material costs and limited domestic supply provided moderate upward support to prices. Producers operated at balanced capacity utilization levels, maintaining a cautiously optimistic market sentiment throughout the quarter. Electrical steel prices in the USA declined by 0.96% in September 2025, mainly due to reduced demand from the transformer and motor manufacturing sectors amid slower industrial and construction activity.

Stable domestic production and comfortable inventory levels further contributed to the mild price correction. Overall, the electrical steel market in the USA during Q3 2025 reflected a softening trend, with expectations of modest recovery in Q4 supported by improving orders from the energy and automotive industries.

United Kingdom: Electrical Steel Domestically traded prices FD-Sheffield, UK, Grade- Non-grain (50WW800) 0.5mm.

According to PriceWatch, in Q3 2025, the electrical steel price trend in the United Kingdom declined as the prices dropped by 1.52% compared to the previous quarter, primarily due to subdued demand from the power infrastructure and industrial manufacturing sectors. Ongoing economic sluggishness and elevated energy costs dampened downstream consumption, while import competition from Asian and European suppliers added further pressure on domestic pricing.

Despite producers’ efforts to manage inventories and production levels, overall market sentiment remained weak, leading to a modest bearish trend across the quarter. Electrical steel prices in the United Kingdom declined by 0.68% in September 2025, primarily due to subdued demand from the power and electrical machinery sectors amid sluggish manufacturing activity.

Adequate domestic inventories and steady imports from European suppliers further limited price support, keeping the market sentiment weak. Overall, the electrical steel market in the UK during Q3 2025 showed a declining trend, with expectations of gradual stabilization in Q4 as industrial activity and energy sector investments begin to recover.

China: Electrical Steel Export prices FOB Shanghai, China, Grade Non-grain (50WW800) 0.5mm.

According to PriceWatch, in Q3 2025, the electrical steel price trend in China declined as the prices decreased by 1.36% compared to the previous quarter, mainly due to subdued demand from the transformer and motor manufacturing sectors. A slowdown in infrastructure and industrial equipment investments, coupled with stable raw material costs, contributed to weaker market sentiment.

Despite steady exports to Southeast Asia, domestic oversupply and cautious restocking activity among end-users exerted downward pressure on prices. Producers maintained moderate output levels to prevent further declines, keeping the market balanced but slightly bearish throughout the quarter. Electrical steel prices in China declined by 1.76% in September 2025, mainly due to weakened demand from the transformer and motor manufacturing sectors amid slower industrial output.

Adequate production levels and steady raw material availability further pressured domestic prices, while export orders remained limited due to global economic uncertainty. Overall, the electrical steel market in China during Q3 2025 reflected a downward trend, with expectations of mild recovery in Q4 supported by anticipated improvements in power equipment and infrastructure demand.

India: Electrical Steel Domestically traded prices Ex-Mumbai, India, Grade- Non-grain (50WW800) 0.5mm.

Accrding to PriceWatch, the electrical steel price trend in India has a decline of 2.32% in Q3 2025 compared to prior quarter due to slowing demand in the power equipment, transformer and motor manufacturing sectors. Weak demand from infrastructure investment and slow project execution have adversely affected domestic consumption.

Price competition from East Asia and steady pricing for inputs exerted additional pressure on Indian producers. While producers attempted to balance inventories and decrease output, the overall sentiment in the electrical steel market have been bearish throughout the quarter. Electrical steel prices in India fell by 0.45% in September 2025 primarily because of steady production activity amid moderate demand for electrical and power equipment.

Ample domestic supply and lower offers from regional suppliers have also contributed to weak price growth, which contributed to a slight downward change in prices. Overall, the electrical steel market in India has been in a slightly bearish market position in Q3 2025, but with a slight expectation for recovery in Q4 as infrastructure and power distribution projects improved in execution.

Thailand: Electrical Steel Import prices CIF Laem Chabang, Thailand, Grade- Non-grain (50WW800) 0.5mm.

During Q3 2025, the Electrical Steel price trend in Thailand showed a slight decrease of 1.14% from Q2 2025 while weak demand from the electrical equipment, appliance, and industrial machinery manufacturing sector became evident. The price declines have primarily been due to subdued infrastructure investments and hesitancy from manufacturers to increase inventory levels, limiting activity.

In addition, stable input costs and the pending import availability from China and Japan continued to contribute downward to prices, making market conditions slightly bearish, while producers cautiously consider production levels as they seek to align supply and demand levels. As a result, electrical steel prices in Thailand fell by 0.95% in September 2025, with the softer trends being attributed to weak demand from the transformer and electrical equipment manufacturing firms amid slower industrial activity.

The price declines have also been attributable to stable supply levels domestically and announced imports from various regional markets exerting a small downward price pressure. Overall, electrical steel in Thailand showed evidence of a softer trend during Q3 and showed signs of stability upon a gradual return of downstream industrial activity from infrastructure projects in Q4.

South Korea: Electrical Steel Domestically traded prices EX-Busan, South Korea, Grade- Non-grain (50WW800) 0.5mm.

In the third quarter of 2025, the Electrical Steel price trend in South Korea declined as the prices decreased by 0.92% from the previous quarter due to decreased demand from the automotive, transformer, and industrial machinery sectors. Weaker downstream demand and relatively stable raw material prices, combined with competitive prices due to imports from China and Japan, contributed to the slight price decline, and producers have maintained controlled production and inventory management in order to minimize the risk of oversupply, which resulted in a slightly bearish sentiment for the market for the duration of the quarter.

Electrical Steel prices in South Korea also dropped in September 2025 by 0.66%, as weaker demand from the automotive and electrical equipment sectors was seen alongside weakening industrial production. Domestic availability has been sufficient while imports have remained stable thus further contributing downward pressure to pricing. Overall, the electrical steel market in South Korea showed signs of weakening in Q3 of 2025 while a moderate stabilization is expected in Q4 as downstream demand improvement is anticipated.